Sunflower oil is golden with refreshing texture. It contains vitamin A, B, D and E, and rich in unsaturated fatty acids. To get the cooking sunflower oil, The basic processes (pretreatment--pre pressing--extracting -- refining) are in need.

The pretreatment process:

Sunflower seed—cleaning—shelling-- shell and kernel separation—flaking—cooking-- pre pressing—crude oil--cake

Pressing process:

Small Capacity Sunflower Oil Press

Medium and Large Capacity Sunflower Oil Press

Refining process:

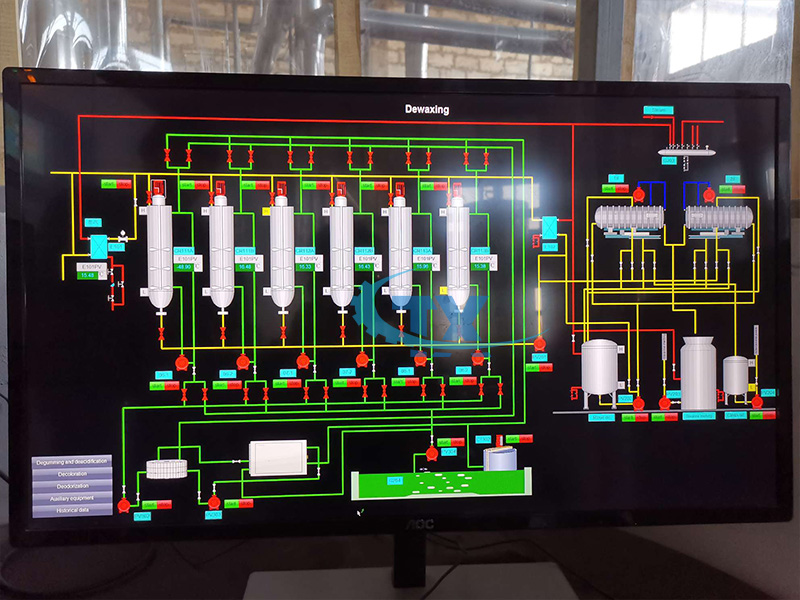

Sunflower seed crude oil→phosphoric acid degumming→washing and drying→dewaxing→decoloring→ physical deacidification and deodorization→dewaxing→ refined sunflower oil

When the sunflower seeds are filtered through the vibrating screen and wind sorting box, they would be sent into the sheller to separate the shell and kernel. After softening, the moisture should be adjusted to 8-9% for flaking. After steaming and frying, sunflower seeds would be sent into the pre pressing process. The oil produced through pre pressing would be refined after filtering and pre pressing cakes are into the extractor to get the sunflower seed meal and crude oil. Then, the crude oil would be sent into refining equipment for crude sunflower oil refinery and dewaxing, then filling in bottles or cans.

When the sunflower seeds are filtered through the vibrating screen and wind sorting box, they would be sent into the sheller to separate the shell and kernel. After softening, the moisture should be adjusted to 8-9% for flaking. After steaming and frying, sunflower seeds would be sent into the pre pressing process. The oil produced through pre pressing would be refined after filtering and pre pressing cakes are into the extractor to get the sunflower seed meal and crude oil. Then, the crude oil would be sent into refining equipment for crude sunflower oil refinery and dewaxing, then filling in bottles or cans.

Henan Taixing Grain and Oil Equipment Co., Ltd. is devoted to researching and manufacturing high quality edible oil processing plant and edible oil production line for our customers in the world. We provide tailored solutions for small scale, medium scale and large scale sunflower oil production line according to your actual situation.