Sunflower seed oil dewaxing process is a process in which sunflower seed oil dewaxing equipment is used to remove wax in sunflower oil to obtain high-quality sunflower oil. Under normal circumstances, the wax content in wool sunflower oil is about 0.06% - 0.2%. These waxes not only affect the transparency and taste of sunflower oil, but also produce peculiar smells during cooking, which affect human health. Therefore, dewaxing of sunflower oil is an important step in the production of sunflower oil. After dewaxing, the wax in sunflower oil is removed, and the value of sunflower oil is also improved. Therefore, most customers choose to dewax the crude sunflower oil.

Sunflower Oil Dewaxing Process

There are many methods for dewaxing oil. At present, the most commonly used is the dewaxing method, that is, freezing crystallization and separation.

Oil to be dewaxed → Cooling and Crystallization → Maturation → Filtration(Wax paste) → Finished oil

Main equipment for dewaxing process

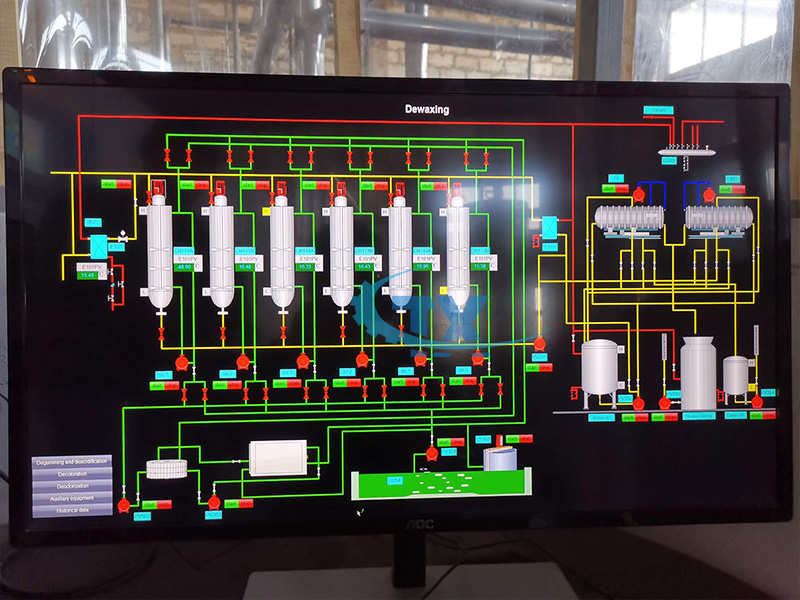

The dewaxing equipment mainly includes refrigeration units, heat exchanger, crystallizing and maturing tanks, and horizontal leaf filter.

Sunflower Oil Dewaxing Technology Process

1. Heating up

Sunflower oil is generally stored in oil tank before dewaxing. The oil temperature is lower than the melting point of the wax in sunflower oil (79-81°C), so some wax has been precipitated in the oil. If the oil is directly used for crystallization and maturation, it will affect the precipitation and crystallization effect of wax in the whole process. In actual operation, first heat the sunflower oil to 85°C to completely melt the precipitated wax in the oil.

2. Heat exchanger

After heating the sunflower oil to completely melt the wax in it, first use a plate heat exchanger to exchange heat with cold water, so as to enter the crystal and maturing tank at lower temperature.

3. Freezing crystallization

The oil is pumped into the crystallization tank at a certain flow rate, and the oil is cooled at a certain cooling rate. After 20 hours, it is cooled to 5-10°C. In order to precipitate the wax during this process, the aggregation and collision between the particles increases, and the oil can be cooled uniformly, need to be properly stirred. but the stirring speed should not be too fast, generally 10r/min during operation.

The cooling rate of the oil must be controlled during the crystallization process. When the oil cools to a certain temperature at a certain speed, the low-solubility high-melting wax in the oil crystallizes firstly, the temperature continues to decrease, the solubility is greater, and the wax with a lower melting point will also precipitate.

4. Maturing and filtration

After the oil is frozen and crystallized to a certain temperature, it is sent to the maturing tank, where the maturing time is maintained for a long time, so that the wax continues to crystallize and the small crystal grains continue to grow. The general crystal growth time is about 10H. Filtering can be performed later, and multiple plate and frame filters or two horizontal filters can be used alternately.

This is the operating process of the sunflower oil dewaxing process. As the wax content of the crude sunflower oil is different, the quality of the refined oil required by the customer is also different, so the technical parameters of the sunflower oil dewaxing process need to be debugged and confirmed by the engineer. If you need to dewax sunflower oil, please contact Henan Taixing. Our engineers will customize the sunflower oil dewaxing process for you and equip the corresponding sunflower oil dewaxing equipment.