Introduction of Soybean Oil Processing Plant

Henan Taixing Grain and Oil Equipment Co., Ltd. - Soybean oil processing machine manufacturer and supplier in China, We supply the whole set soybean oil processing machine composed of soybean oil pretreatment and pre-pressing machine, soybean oil solvent extraction plant and soybean oil refinery plant. We have a wealth of experience in designing and manufacturing various kinds of soybean oil machine. We can customized soybean oil processing machine according to the customer requirements.

Soybean oil production line is a process in which soybeans are treated by pressing or solvent extraction method to obtain crude soybean oil and then refined to obtain edible soya oil.

The two oil production methods have different application scenarios and advantages and disadvantages, please contact us to provide you with a more suitable and complete soybean oil production line solution.

Soybean pretreatment workshop is the basic process of soybean oil processing machine, is mainly to remove impurities in soybean, regulate moisture and temperature of soybean, and break soybean into small particles to change soybean molecular structure, etc, which is good for the following process in solvent extraction workshop. After soybean oil pretreatment & prepressing machine, we can get soybean cake. Soybean cake can go to the following solvent extraction workshop. Soybean cake also can be used for extracting protein.

Photos show of soybean oil pretreatment and pre-pressing machine:

Soybean oil pressing process is a mechanical extraction method by using a screw press to squeeze oil out of pre-treated and clean soybeans under pressure. The daily capacity of the screw press varies from 1 ton to 50 tons, and it is the most commonly used method for continuous mechanical extraction of oil and grease. Usually, the oil yield of the physical press method is 65%-70%, which is suitable for small commercial processing plants and medium-sized screw press oil plants.

Main process of soybean oil pressing process:

Soybean pretreatment->Pressing->Filtering->Crude soybean oil

Soybean Oil Solvent Extraction Plant

Soybeans have a relatively low oil content (15-22%). To obtain more oil and considerable economic benefits, soybean extraction is generally used to produce soybean oil. The extraction method mainly uses solvent oil (hexane) to fully soak the treated soybean, so that the oil in the soybean is extracted. After extraction, the residual oil in the cake is generally less than 1%. Soybean meal cakes can also be used to process animal feed.

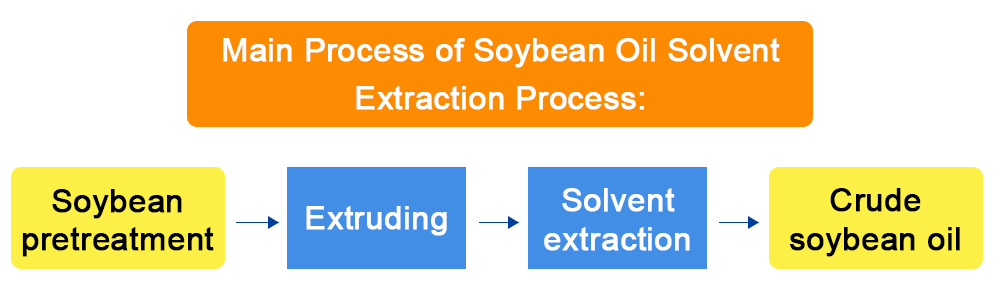

Soybean oil solvent extraction process flow diagram:

Pressed cake→Solvent extraction system→D.T.D.C system→Condenser system→Recovery system→Crude soybean oil

Photos show of soybean oil Solvent Extraction Plant:

Soybean oil refinery plant includes a series processing process such as degumming, neutralization, bleaching, deodorization and so on. In general there are two methods of soybean oil refining process, one is physical refining and the other is chemical refining. However, no matter what kinds of refining methods, they are all done with the help of various oil processing equipment and machinery. What’s more, soybean oil refining machine are used to refine almost all kinds of oil extracted from oil seeds like sunflower seeds, peanuts , sesame seeds, and soya bean seeds etc. After refining, we can get refined, bleached, deodorized oil. That is, first-grade soybean oil.

Refining process:

Soybean crude oil-- phosphoric acid degumming—washing and drying—adsorption and decolorization—distillation and deodorization—filtration-- refined oil

Photos Show of Physical Soybean oil Refining plant

Photos Show of Small Chemical Soybean oil Refining plant

Henan Taixing Machinery can provide a whole soybean oil production line for you if you want to produce high-quality soybean oil, you can contact us, and we can offer you a whole line of soybean oil pretreatment equipment, soybean oil extraction machine, soybean oil refinery machine, build a turnkey project from A to Z for you.