Corn germ is a general kind of material for making edible oil and the oil content of corn germ is 30%-48%. The whole corn germ oil production line contains three plants: corn germ pretreatment plant, corn germ oil extraction plant and corn germ oil refinery plant. The following picture shows the machines used in corn germ oil production line.

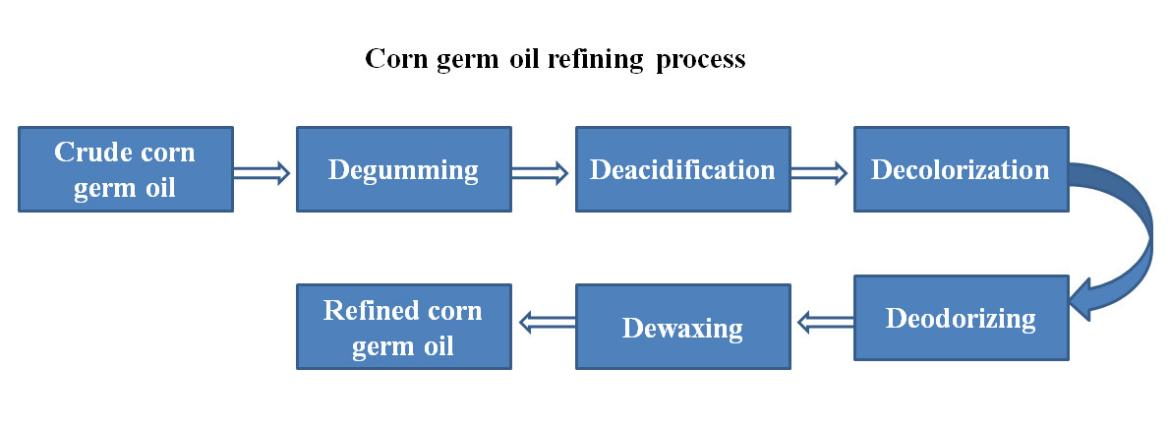

Crude corn germ oil degumming:

In this step gums in crude corn germ oil are removed by hydration with the help of phosphoric acid.

Deacidification ( neutralization):

In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap.Additional impurities are also removed by adsorption on soap.

Decolorization:

During decolorization, unwanted pigments are adsorbed physically and oil will become much clearer.

Deodorization:

Deodorization is used to remove unacceptable odors by steam distillation, the odoriferous compound are stripped off with the help of live injected steam into heated oil under high vacuum pressure.

Dewaxing (necessary for cold areas)

Some kinds of oil like sunflower, maize germ or corn oil have to waxes inside, if these impurities are not removed, the oil will freeze easily under low temperature, thus effecting oil quality and appearance.so this process is necessary in extremely cold areas.

Major equipment in corn germ oil refinery plant:

Degumming tank, Deacidification tank, Centrifuge, Heat conducting oil boiler, Decolorization tower, Deodorization tower, Vacuum pump, Air compressor, Air press, Steam generator, Filter

Functions of corn germ oil refinery plant main parts:

(1) Refining section: used to P-acid de-gumming, alkali refining de-acid and water rinsing.

(2) Decoloring section: used to remove off pigments, bleaching oils and grease dehydrate.

(3) Deodorizing section: to remove off the odor components in oil.

(4) Dewax: used to remove off the wax in the oil, in order to get the high quality oil.

(5) Heat-transfer oil stove: supply each device production needing heat energy, temperature reach above 280°C.

(6) Steam generator: produce the needing steam for de-odoring and distillation.

(7) Vacuum pump: supply needing vacuum for dehydrate, de-color, de-odor. Vacuum degree can reach above 755mm Hg.

(8) Press filter: filter clay, filter out clear oil.

(9) Air compressor: blow dry bleached clay, blow empty the leftover oil in the press filter.

Working process of corn germ oil refinery plant:

1.pump crude corn germ oil into refining tank and heat with conduction oil, and the temperature will reach about 70°C-80°C after one hour.

2.Add acid or alkali to separate according to the acid value. After one hour's processing and 4-6hours deposit, then convey soap stock to storage tank.

3.Pump refined corn germ oil into decolorizing tank. When it is up to 90-110°C after one hour's heating, add clay into tank for 20min's processing. Then separate clay and oil with filter.

4.Put discolored corn germ oil into deodorization tank with vacuum pump. Heat and process with steam for odor removal. After filtering, you will get final oil product.

Advantages of corn germ oil refinery plant:

1. The impurity of oil must be less than 0.2% after refining;

2. Recycling system save power and money;

3. Lower oil waste.

As a professional edible oil refinery plant manufacturer, our engineers can provide professional technical support for your corn germ oil refinery plant. And Henan Doing Company is able to provide 1-1000TPD corn germ oil refinery plant.

Beside, the corn germ oil refinery plant can work independently or together with the whole corn germ oil production line.

4. Newest technology and automatic

As a professional peanut oil refinery plant manufacturer who is devoted to studying peanut oil refining process, we can provide professional technical support and manufacture first rate oil machines for customers from all over the world. And our peanut oil refinery plant capacity can be customized. The complete peanut oil refinery plant can work independently or together with the whole peanut oil production line. If you need machines for producing peanut oil, welcome to inquiry and visit!