Introduction to Cottonseed Oil Processing Plant

The technological process of Cottonseed oil processing plant includes the following steps: cottonseed pretreatment, cottonseed oil pre-pressing and cottonseed cake solvent extraction, and crude cottonseed oil rehnery plant.The final products of the cottonseed ol processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock.

Features of Taixing’s Cottonseed Oil Processing Plant

1. High automation degree, continuous operation, saving labor;

2. The pre-pressed cake has low residual oil rate and is easy for solvent penetration;

3. Cottonseed oil extraction plant has multiple oil extractors for selection and advanced mineral oil system4. Adopting negative pressure evaporation system, saving energy and reducing steam consumption5.Low residual oil rate in the meal, good oil, and meal quality.

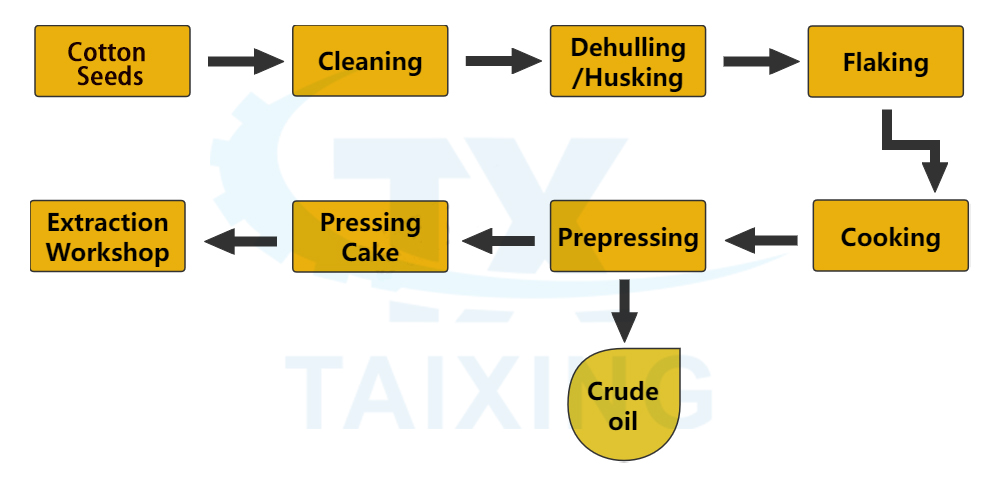

Cottonseed Pretreatment and pre-pressing Process

The purpose of cottonseed pretreatment is to clean up the impurities in cottonseed, adjust the moisture, temperature and internal structure of cottonseed, so that cottonseed can reach the good state before being squeezed, and then improve the cottonseed oil production efficiency.

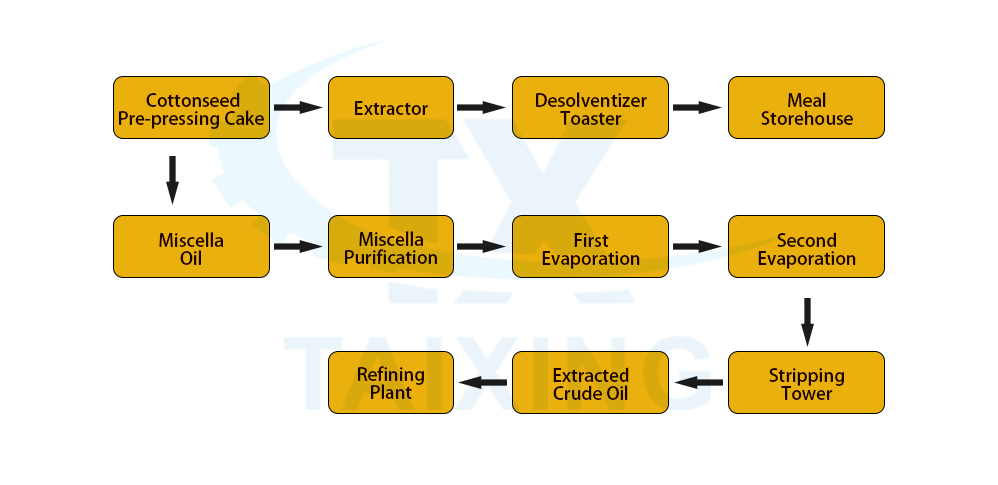

Cottonseed Cake Solvent Extraction Process

Cottonseed Cake Solvent Extraction Process is using the organic solvent to extract ol from the pre-pressed cake inside the oil extractor. Multiple oil extractors such as loop type extractor, rotocel extractor and towline extractor can be used for the cottonsed oil extraction plant, After oil extraction, miscella and the solvent containing wet meal are obtained. The miscella is pumped into the hydrocyclone to remove the fines and then the miscela enters the miscella tank in the cottonseed oil extraction plant.

Cottonseed Oil Refining Process

The purpose of cottonseed oil refining is to remove the gum soluble impurities, free fatty acid, pigment, peculiar smell and other impurities in cottonseed oil, so as to improve the stability and value of cottonseed oil. The basic cottonseed oil refining process includes degumming, deacidification, decolorization and deodorization. Cottonseed oil refining machine mainly has three types, bathc type, semi-countiuous type and continuous type. After refining, cottonseed oil meeting national standards can be obtained and sold on the market to obtain profit income. So far, the technological process of cottonseed oil production by solvent has also ended.