What is a Palm Oil Refining Plant?

It's an industrial facility that processes Crude Palm Oil (CPO) into Refined, Bleached, and Deodorized Palm Oil (RBDPO), making it safe, stable, and suitable for human consumption or further industrial use. CPO from mills contains impurities like gums, free fatty acids (FFA), pigments, odors, and waxes that must be removed.

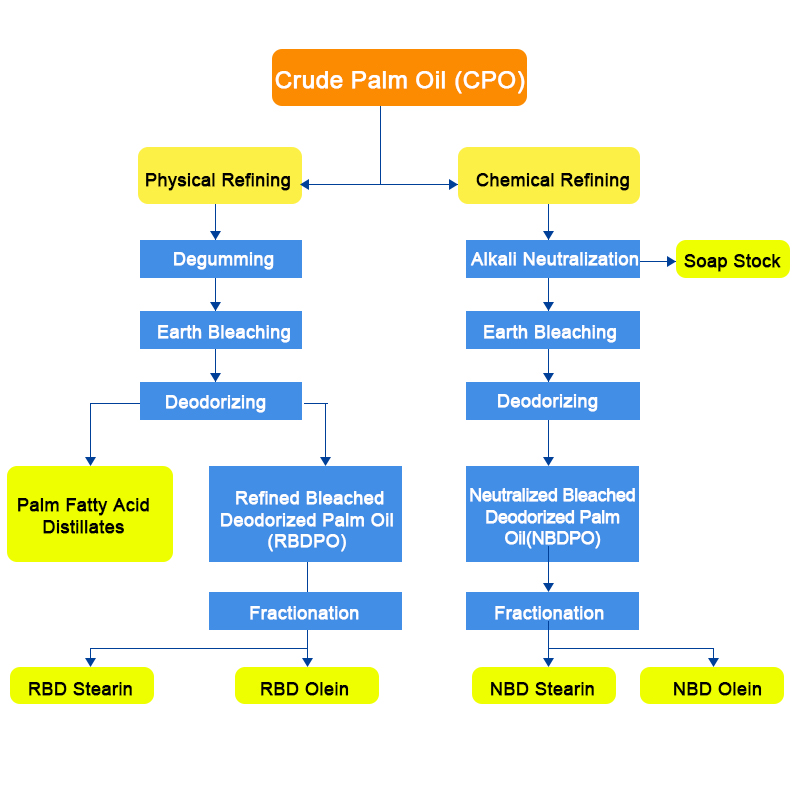

The Two Main Palm Oil Refining Processes

Palm Oil Physical Refining Plant(Most Common)

Dominates the industry because palm oil typically has high FFA. Physical refining plant is more economical and environmentally friendly (less chemical use, higher yield).

Physical Refining Plant Process Flow:

1. Degumming: Water or phosphoric acid is mixed with CPO to hydrate and remove phosphatides (gums).

2. Bleaching: The oil is heated and mixed with bleaching earth (clay) under vacuum. The clay absorbs pigments (carotenes), soaps, and oxidation products.

3.Filtration: Spent bleaching earth is filtered out.

4. Deodorization (and Deacidification): The core step. Under high vacuum and high temperature (240-260°C), steam is injected. This strips away volatile components: FFA (acid removal), odors, and flavors. The FFA is recovered as Palm Fatty Acid Distillate (PFAD), a valuable by-product.

5. Output: RBDPO (Refined, Bleached, Deodorized Palm Olein/Stearin).

Palm Oil Chemical Refining Plant

Chemical Refining

More suitable for oils with low FFA or high phosphatide content (like soybean). Less common for palm oil today.Advantages of CPO Physical Refining Technology

As we all know, the palm oil fruit can yield two distinct edible oil - palm oi that is obtained from the outer part of the palm fruit and the palm kernel oil that is derived from the inter kernel of the palm fruit (palm nut). Physical refining process is suitable for both crude palm oil and palm kernel oil.

Improve production capacity and refining rate.

- Reduce production cost.

- Shorten processing time.

- Directly recovering highly purified distilled fatty acids.

- Reduce waste water and waste gas problems. There is no waste water and waste gas produced by the cracking of soap feet in chemical refining plant.

Palm Oil Fractionation(Optional)

RBDPO is cooled under controlled conditions to crystallize and separate into:

Palm Olein: Liquid fraction (used for cooking oil).

Palm Stearin: Solid fraction (used in margarine, shortening, soap).

Types of Palm Oil Refining Plants & Capacity We Supply

Batch Plants: Small capacity (<50 TPD). Simple but less efficient.

Semi-Continuous Plants: Medium capacity (50-200 TPD). Good flexibilit.

Fully Continuous Plants: Large capacity (>200 TPD). ost modern, efficient, and automated. Standard for new installations.

About Problems of Palm Oil Refining Process We can Solve

√ High energy consumption / Steam usage.

√ Inconsistent final oil quality (color, FFA).

√ Low yield / High oil loss in by-products.

√ Downtime and maintenance headaches.

√ Difficulty meeting RSPO or food safety standards.

Unique Selling Propositions of Henan Taixing Palm Oil Refining Machine

Energy Efficiency: "Integrated heat recovery system reduces steam consumption by up to 30%."

Superior Yield: "Patented fatty acid distillation design maximizes RBDPO yield and PFAD purity."

Advanced Automation: "PLC-controlled with SCADA system for one-touch operation, recipe management, and remote diagnostics."

Premium Components: "Core vessels & pumps from European brands (name them if possible) for guaranteed longevity."

Flexible Design: "Modular skid-mounted design for easier installation and capacity expansion."

Safety & Compliance: "Full NFPA or ATEX compliance for dust explosion prevention (critical for bleaching section)."