Palm oil mill process is quite different from other oil seeds processing. Palm oil mill process includes 6 parts: Palm fruits receiving, sterilizing, threshing, digesting and pressing, crude oil clarifying and palm kernel recovery.Our palm oil mill process is low cost and energe-saving.

Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, where a palm oil mill plant commonly handles 15-100tph of FFB.

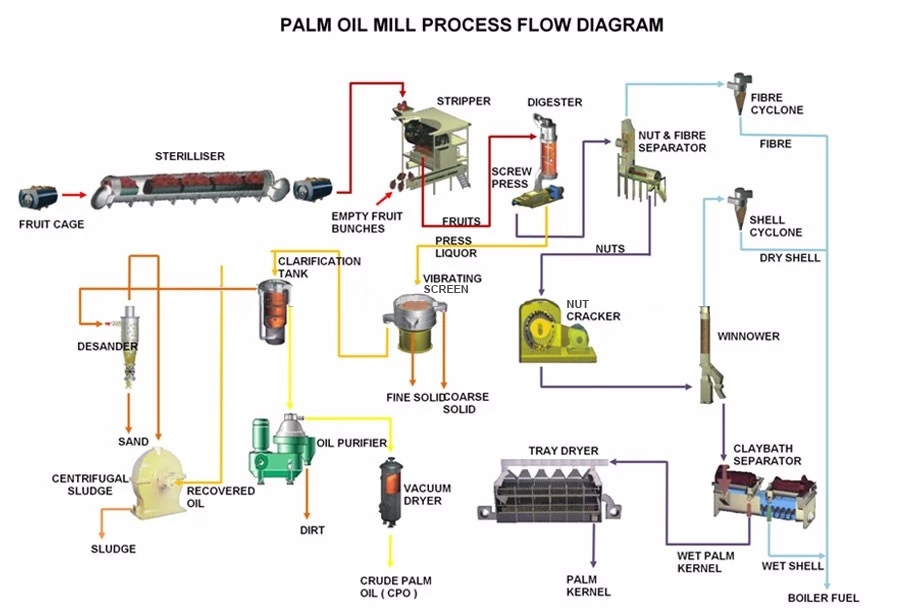

A typical palm oil mill has many operational units as shown in Figure 2. This comprises of sterilization, threhsing, digesting and pressing, clarification, purification, drying and storage. For the palm kernel oil production line, there are steps such as nut/fiber separation, nut conditioning and cracking, cracked mixture separation, and kernel drying and storage. The dried kernels are often sold to palm kernel crushers for extraction of crude palm kernel oil. In some integrated plants, kernel crushing facilities exist side by side in the same complex.

Production capacity: 15-100TPH

Palm oil mill process flow chart as follows:

Large-scale palm oil mill plants, featuring all stages required to produce palm oil to international standards, are generally handling from 60 to 120 tonnes of FFB/hr. The large installations have mechanical handling systems (bucket and screw conveyers, pumps and pipelines) and operate continuously, depending on the availability of FFB. Flow chart of the palm oil mill process is shown as follows:

1.Raw material reception:

As for the first step of palm oil mill process,collecting the FFB and convey by trucks, then pour the fluster into the discharge door after weighed.

2.Sterilization:

FFB are airtight sterilized in sterilizer of palm oil mill process, the purpose is to prevent enzymes broken down, avoiding FFA content in oil further increase.

3.Threshing:

The purpose of threshing in the palm oil mill process is to separate the palm fruit from the FFB. The drum type thresher is the usual machine to separate the fruit.

4.Digesting and pressing:

The purpose of digesting in the palm oil mill process is to separate the pulp and nut and crush the palm pulp. Then it is sent to continuous screw press. After pressing of palm oil mill process, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).

5.Oil clarification:

As for the oil clarification of palm oil mill process,oil is clarified by the vibrate screen.

6.Kernel recovery:

As for the last step of palm oil mill process, The separated fiber material is sent to the boiler room as fuel; the separated kernel is transported to kernel warehouse by pneumatic conveying system for temporary storage.

We will choose the palm oil mill process according to the different requirements of different customers. Both technical and economic effects are taken into account while plan the palm oil mill process, so that to build the best palm oil mill plant, Henan Doing Company is your best choice. After processed through the palm oil mill process,the crude palm oil can be sold or deeply processed.

Building 10, Enterprise Park, Hi-tech Zone, Zhengzhou City, Henan province, China