Main Machines

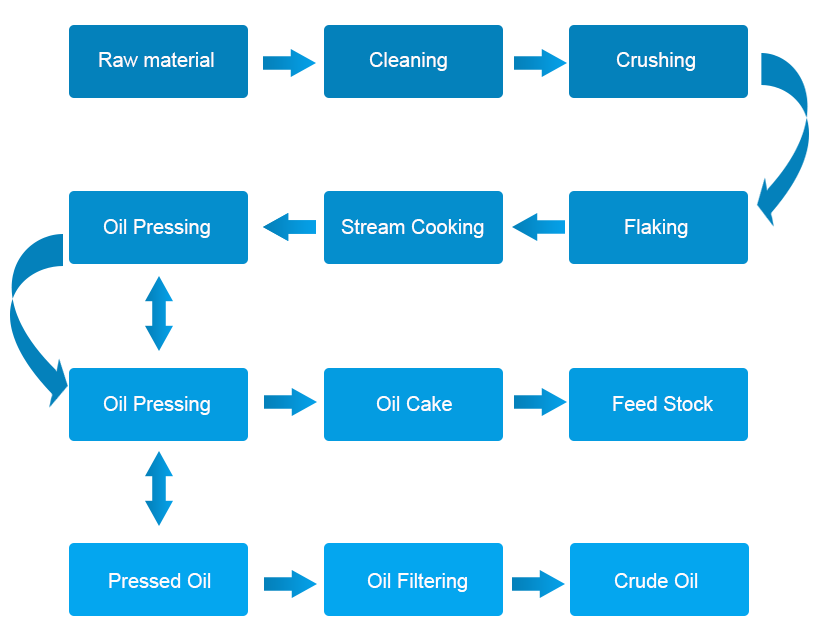

An oil expeller press (also called a screw press) is a mechanical device used to extract oil from oilseeds and nuts through continuous compression and friction. It's one of the most common methods for small to medium-scale oil extraction, bridging traditional methods and large-scale industrial solvent extraction.

Screw oil press is a compact-structured oil expeller machine used for extracting edible oil from more than twenty kinds of oilseeds such as peanut, soybean, flaxseed, sunflower seed, rapeseed, palm, palm kernel, etc. Different from integrated screw oil press machine, it is more suitable to large-scale cooking oil plants which produce various grades cook

Knew as sesame oil expeller, hydraulic oil press adopts hydraulic principle to produce pure and assured edible oil. The whole cooking oil expelling process is visible and needs only about 5-7 minutes; It is available to sesame, walnut kernels, pumpkin seeds, kiwi seeds, tea seeds, and almonds, etc.

Oilseeds cooker is the processing equipment for put tbe embryo into mature embryo by wetting and cooking, to meet the needs of oil extraction machine. Our oilseeds cooker can also be used as softening

Oilseeds crusher mainly adopts toothed roll crusher, is a kind of new models for soybeans and other granular oilseeds system in the process. Crushing the granular oilseeds by the oilseeds crusher, it

Oilseeds cleaning sieve is mainly primary cleaning the impurity.Main structure of Oilseeds cleaning machine: High efficiency vibration oilseeds cleaning sieve mainly consists of the frame, feed box, vibration motor, machine body, discharging box and other parts.