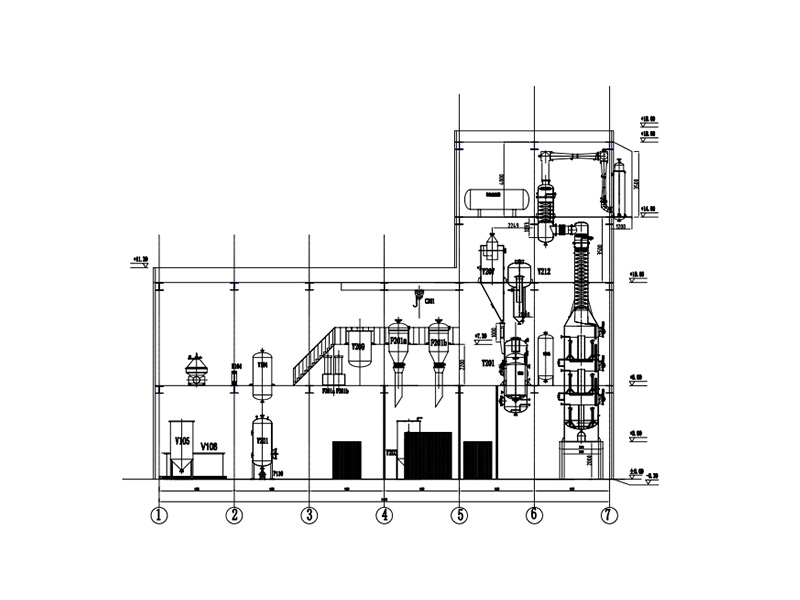

Sunflower Oil Refinery Process

1.Degumming

colloidal impurity will affect the stability of sunflower cooking oil and it can be removed by adding a certain amount phosphoric acid solution, which can make the colloidal impurity absorb water for cohesion.

2.Deacidification

it is used to remove the free fatty acid in the sunflower cooking oil.There are chemical way and physical way to choose from. Chemical deacidification is carried out by adding lye; physical deacidification is carried out by pumped into high-temperature water vapor.

3.Decolorization

In this section, white clay is usually added to sunflower cooking oil and the adsorption of white clay will remove the pigment in the oil.

4.Deordorization

After bumping high temperature water vapor, odor substances can be removed by virtue of volatility difference, so as to improve the quality and flavor of sunflower cooking oil.

5.Dewaxing

The wax in sunflower cooking oil affects the flavor and taste of the oil, so it requires dewaxing operation. At present, the commonly used dewaxing method is freezing crystallization method.

After the above five refinery steps, we can obtain sunflower cooking oil that meets national standards and can be sold on the market.

In sunflower cooking oil refinery process, there are mainly three types sunflower cooking oil refining machine can be chose: batch type refining machine, semi-continuous type refining machine and full continuous type refining machine. We suggest you to select sunflower cooking oil refining machine according to processing capacity and investment budget.

Henan Taixing Grain and Oil Equipment Co., Ltd. Founded in 1983. We have has years of experience in manufacturing and installing cooking oil refining machine, which can meet different sunflower cooking oil purification needs. If you are interested, welcome to contact us, our professional team of engineers can customize the best sunflower cooking oil refining machine and processing solutions for you!