Building 10, Enterprise Park, Hi-tech Zone, Zhengzhou City, Henan province, China

Waxes, naturally present in seeds like sunflower and rice bran, can cause cloudiness, sedimentation, and an unappealing appearance in the final bottled oil. More importantly, they can negatively impact the oil's flavor stability and shelf-life.

Maximize the quality and market value of your sunflower, corn, rice bran, shea butter oil and other oils. Henan Taixing Grain and Oil Equipment Co., Ltd. designs and manufactures industrial-grade dewaxing systems that deliver unmatched efficiency and reliability.

Advanced Dewaxing Technology for Superior Results

We have perfected the cooling, crystallization, and filtration process to deliver maximum wax removal with minimal oil loss.

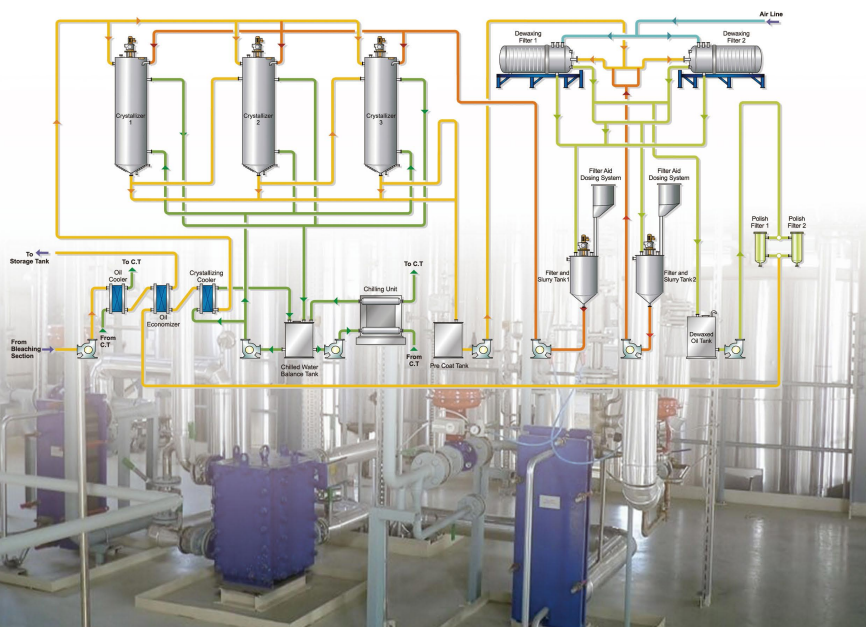

Our Precision Process:

1.Controlled Cooling & Crystallization: The oil is slowly and precisely cooled under controlled agitation, allowing wax crystals to form to an ideal size for easy filtration.

2.Efficient Separation: The oil is passed through our specialized filter presses or other separation technologies, effectively trapping the wax crystals.

3.Brilliant Final Product: The result is a brilliantly clear, winterized oil ready for the final stages of production and bottling.

Our advanced dewaxing machines remove these undesirable waxes and sediments, ensuring your product meets the highest standards of:

Brilliant Clarity: Produce visually stunning, sediment-free oil that consumers trust

Extended Shelf-Life: Improve oxidation stability for longer-lasting quality.

Enhanced Filterability: Prevent filter clogging and increase production efficiency.

Higher Market Value: Command better prices with a premium, refined product.