Building 10, Enterprise Park, Hi-tech Zone, Zhengzhou City, Henan province, China

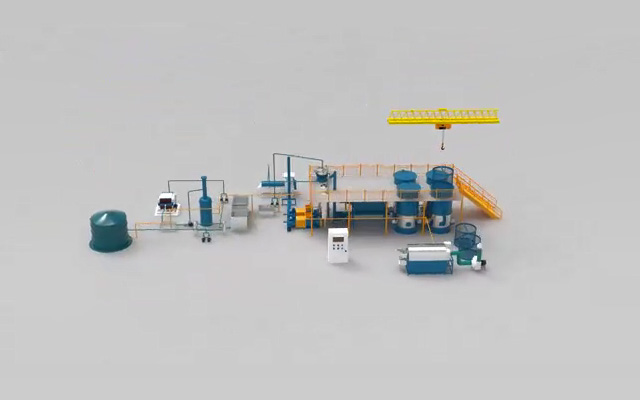

With over 25 years of existence in our field, we have gained incredible expertise in providing services in terms of process development, technical evaluation studies, design of plants, oil refinery equipment, improvement and expansion of existing facilities, studies from the point of view of pollution prevention, energy conservation and staff training.

We follow an authentic and effective approach to fulfill customer’s requirements of services related to engineering, technical and project management. Our customer centric approach has motivated us to make use of latest available technology while executing turnkey projects for our clients.

At Taixing Machinery, we have technically experienced and qualified team who will give special attention in understanding and designing the plant.

The design is finalized either by the standard capacity or by customized approach. Based on this, the construction and making work begins. The manufacturing department starts the production work for the equipments. All the pressure vessels and machinery is manufactured by International Standards and extreme care is ensured on fabrication work.

We recognize the fact, that after supply of the plant INSTALLATION is very important for successful running of the plant to achieve the desired output. For the said reason to ensure successful commissioning, we send our most experienced Commissioning supervisors . During their stay at the sight, they not just supervise the entire commissioning job, but provide training to the local plant operators /engineers, about the nitigrity of the plant, functioning of the same and also how to handle and resolve any operating issues of the plant in case of emergency.

The client keeps all the utilities and raw materials ready for the testing. The test batch trial production is started and commenced. The startup is carefully checked and continued for almost 5 days to make sure things are smooth.

Our engineers will also provide the guidance to the local operators on the handling and operations. The fault detection and troubleshooting are the part of Startup Process and they are addressed if any.

We successfully hand over the plant to the client for the future continued usage and remain available for any after sales activity or any other assistance.