Building 10, Enterprise Park, Hi-tech Zone, Zhengzhou City, Henan province, China

Create High-Value Specialty Fats with Precision Separation

Oil fractionation equipment can be used to process shea butter oil, palm oil, palm kernal oil, cottonseed oil and other vegetable oil, fish oil, butter, lard and other animal fats, thereby greatly improve the added value of the oil products.

What is Oil Fractionation?

Fractionation is a critical physical refining process that separates natural oils into two or more distinct components (fractions) with different melting points and properties. This is achieved through controlled crystallization and filtration.

Our Fractionation Technology--Dry Fractionation

Our dry fractionation process, known for its efficiency and absence of chemicals, is the industry standard for oils like Palm.

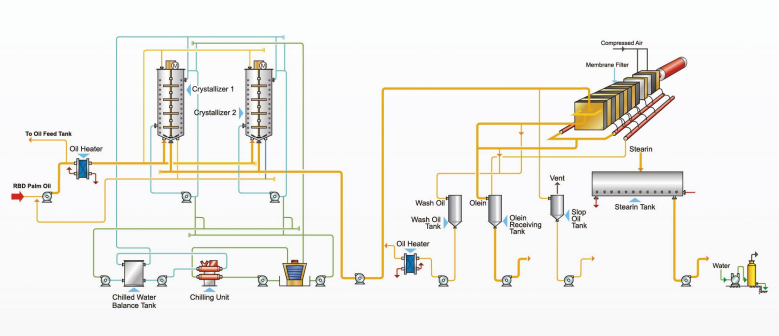

Our Precision Dry Fractionation Process:

1.Precise Melting & Cooling: The oil is carefully melted and then cooled under a meticulously controlled cooling curve with continuous agitation.

2.Targeted Crystallization: This stage encourages the formation of stable, filterable crystals from the higher-melting triglycerides (Stearin).

3.High-Pressure Separation: The crystal slurry is fed into our heavy-duty membrane filter presses, which efficiently separate the liquid fraction (Olein) from the solid fraction (Stearin).

4.Distinct Final Products: You get two (or more) marketable products from one raw oil, each with its own applications and value.

Tailored Fractionation Solutions for Your Needs

We provide complete, turnkey fractionation plants designed for optimal performance and a quick return on investment.

Palm Oil Fractionation Plants: The most common application, producing Palm Olein (liquid) and Palm Stearin (solid).

Palm Kernel Oil Fractionation Plants: For producing PK Olein and PK Stearin.

Multi-Stage Fractionation Systems: For producing super oleins, mid-fractions, and other specialty fats with very specific properties.

Batch & Continuous Systems: We design solutions tailored to your capacity, from modular batch systems to fully continuous, automated plants.